REDFIELD, Iowa — The Redfield brickworks is slated to close Tuesday, Oct. 29, bringing to an end almost 150 years of brick making in this southwest Dallas County town of 835.

The Glen-Gery Corp., which acquired the Redfield plant in 1988, was itself acquired last year by Brickworks Limited, Australia’s largest brick maker, in a deal valued at about $103 million.

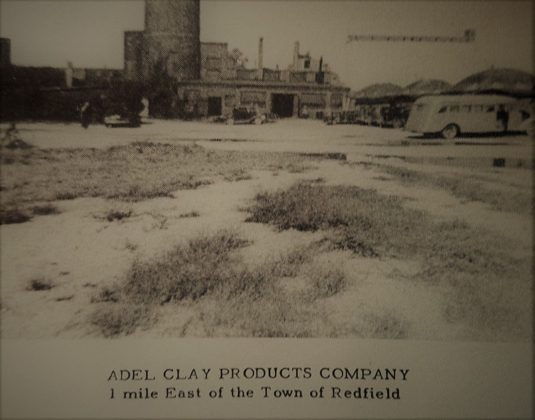

The Redfield facility is believed to employ about 20 workers. Tim Leese, a Glen-Gery spokesperson in the company’s Reading, Pa., offices, could not confirm the number of Redfield employees or say whether the workers would be laid off or transferred to the United Brick and Tile plant in Adel, which Brickworks Limited acquired in August of this year with its $32 million purchase of Sioux City Brick, which had owned and operated the Adel plant since 1958.

The final days at the Redfield brickworks took on a more somber air with the sudden death Oct. 17 of the plant’s 50-year-old manager, Steven Klinkefus of Humboldt.

Evidence suggests humans have been building with bricks for about 10,000 years. Much of the modern process of brick making is automated, but the process of manual brick making is still practiced in some parts of the world much as it was in Redfield some 150 years ago.

Redfield has been producing its high-quality bricks and field tiles since the 1870s, according to Pete Malmberg, historic and cultural resources coordinator for the Dallas County Conservation Board and staff assistant to the Dallas County Historical Commission.

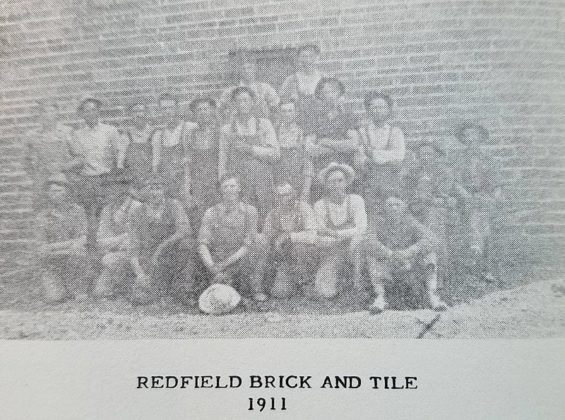

Among Dallas County’s rich resources are the high-quality red and blue clay and shale deposits left behind about 11,000 years ago by the retreating Wisconsin glacier. Open-pit extraction of this high-iron shale, which turns a rich red when fired, quickly earned the local bricks the name Redfield Reds.

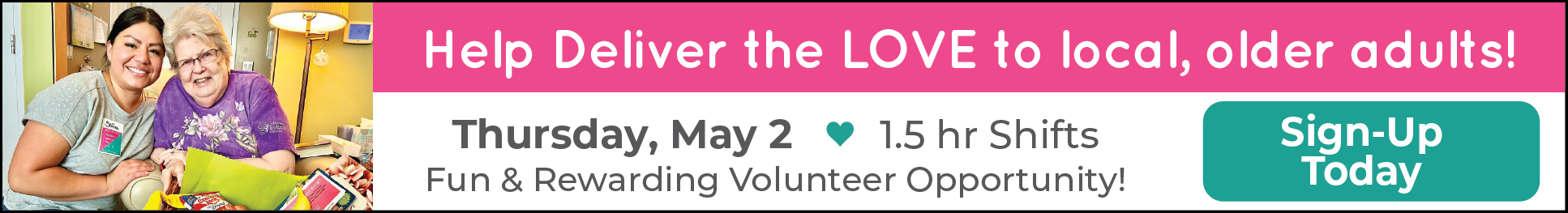

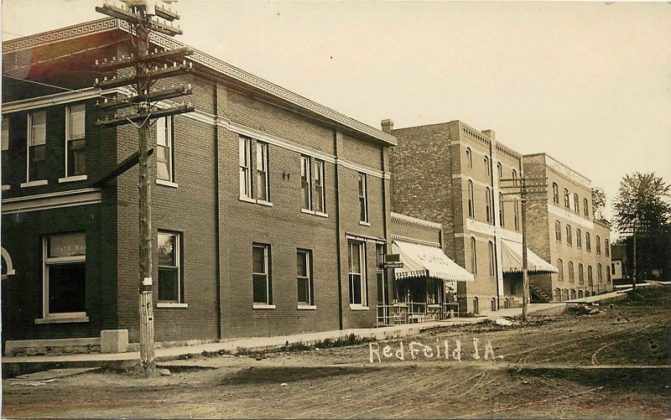

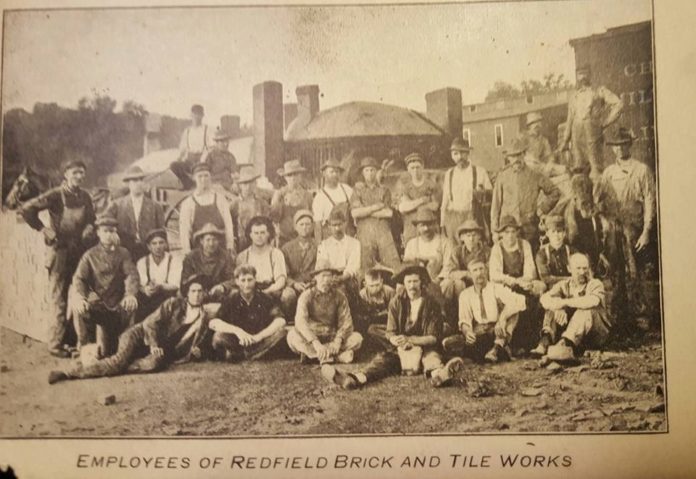

According to Malmberg, the Goodwin and Myers Brick and Tile Co. began operating a brickworks in Redfield in 1894, and Robert Goodwin assumed full control over the plant in 1901, changing the name to the Redfield Brick and Tile Works.

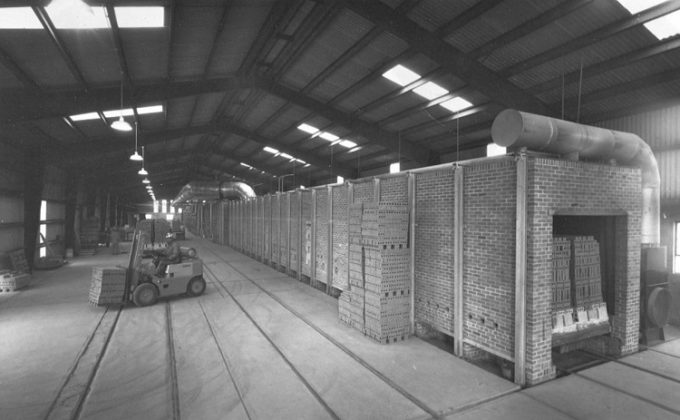

The Redfield factory was expanded steadily over the years. In the early days, bricks were produced by the soft-mud or molding method and fired in beehive-style kilns. Millions of field tiles were also produced at the plant and used for draining Iowa’s farmland. The plant operated only six months each year, and employees worked at the local ice house during the winter.

A 1908 fire destroyed the number one building, according to Malmberg. Newspapers reported more than $20,000 in damage to buildings, equipment and materials, and rebuilding took six months. The factory became a year-round operation in 1940, greatly increasing job stability. By 1960 there were some 60 employees at the Redfield brickworks.

A modern drainage-tile plant was constructed in 1968, featuring a continuous tunnel kiln. Two years later, a second tunnel kiln for brick production was added. Both of these plants were designed by ceramic engineer Wayne Barrett. The old beehive kilns were gradually phased out until production completely stopped in the early 1970s.

The Goodwin family sold their interest in the Redfield factory in 1970 to Texas-based Cantex Inc., which in turn sold out in 1982 to an Australian firm, Midland Brick. As noted, Glen-Gery Corp. acquired the brickworks in 1988, and Brickworks Limited bought Glen-Gery in 2018.

Not only can high-quality Redfield bricks be found in the Google headquarters in Mountain View, Calif., but the company’s products also helped to build many notable buildings over the decades, including Father Flanagans’ Boys Town near Omaha, numerous buildings on the Iowa State University campus in Ames and the Garst and Thomas Pioneer Seed Corn factory in Coon Rapids.

The Adel brick factory currently employs about 100 workers and produces about 250,000 bricks daily.

The original Redfield brickyard with its beehive kilns today sets empty and overgrown but not wholly forgotten. Malmberg said he is exploring ways to preserve the old brickyard as an industrial history site.

The closure of the Redfield plant will still leave Brickworks Limited with 10 brick manufacturing plants and one stone manufacturing plant across the northeast and midwest regions of the U.S. The company sells about 320 million bricks a year in North America.